NEWS & EVENTS

NEWS & EVENTS

Media Spotlight FIDIC Awards Presented to Subway Line 10 and Design for Urban Construction Once Again Becomes the Focus of Attention

On November 24, Tian Dong, deputy chief engineer of Beijing Urban Construction Design & Development Group Co., Limited’s Rail Traffic Institute and person in charge of the design of the second phase of the Subway Line 10 in Beijing, was interviewed by media from BTV, Beijing Daily, China Construction News, Beijing Development and Construction News, www.qianlong.com and periodical of Construction Technology. When asked about the features and highlights of the design, the importance of the awards in the international design and consultancy industry, and the stories behind the designing course, Tian Dong answered the journalists’ questions with full and accurate information and in a humorous manner. With the answers winning wide acclaim among the journalists, the interview was selected headline of the www.qianlong.com.

On November 25, coverage of the event in great length appeared on all media. On November 28, BTV broadcast the news, and the news was also widely spread by news networks such as www.xinhuanet.com and www.qq.com. “FIDIC Awards Presented to Line 10 of the Beijing Subway” and “Design for Urban Construction in Beijing”attracted the gaze of people!

Line 10 of the Beijing Subway Wins The “Nobel Prize” of Engineering Design and UCD Demonstrates Outstanding Professional Proficiency

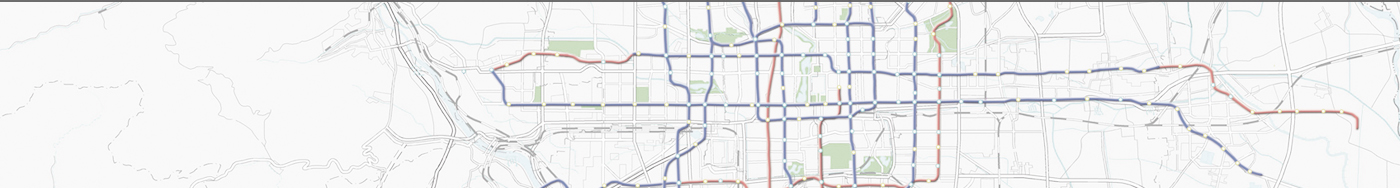

The Line 10 of the Beijing subway is currently the biggest closed underground loop line in the world and is also the second loop line of the rapid passenger transport network in Beijing. The total length of Line 10 comes to 57.11 kilometers, with 45 stations along the line, 24 of which are transfer stations. According to the original network planning, Line 10 and Line 11 were two independently operated loop lines. Proceeding from the actual needs of the urban area, the project team mapped out the physics loop for the two lines and built the second loop line in Beijing, making it the longest underground line in the world.

Sketch Map of Line 10

Despite the lingering construction period, poor geological conditions, sensitive and complicated surroundings, extreme difficulties in engineering technology and environmental protection, UCD surmounted loads of difficulties that cropped up in construction through ingenious, novel and rigorous design and, by taking “Innovating of Ideas, Technologies and Operation” as its guiding principle, UCD has given full expression to the “people-centered, green and sustainable”philosophy in rail traffic construction and made their work a parallel to world advanced levels.

Using Excellent Technical Strength to Combat Difficulties

Since the construction needed to be carried out by stages, the integration of Line 10 and Line 11 was to be completed without the first phase of the construction being brought to a halt. As a consequence, construction could only be done within 3.5 hours at night. For this reason, all sectors of UCD gradually elaborated the implementation plan, tenders in the later period and the working drawings across the board and in various angles, including supply of goods, scope of services, connection to the first phase and remolding, investment, adaptability, difficulty, risks and degree of convenience to the operation, etc., thereby making the integration and the opening of the loop line to traffic a complete success.

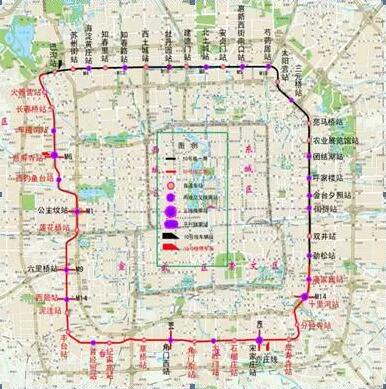

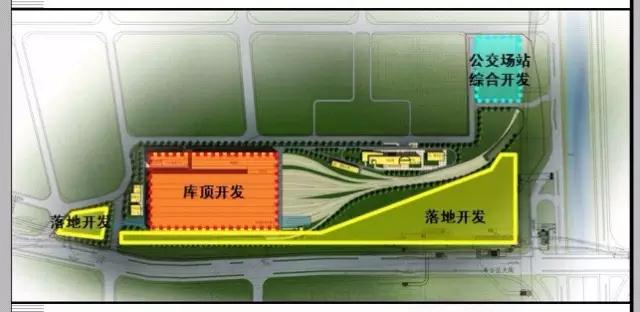

The ground and underground overlapping double-deck garage has been adopted for 5 stations, with property development being conducted on the garage. By means of design, optimization and integration, the area of the construction land has been reduced from 25 hectares to 12 hectares, saving a raft of land resources for the development of urban public facilities and properties. Meanwhile, with throat areas being covered with greening, sound-proof walls and blinds erected on both sides, and anti-vibration pads laid under the tracks, the subway noises have been totally fenced out, creating a new paragon for resource-intensive, environment-friendly and technically innovative vehicle bases combining ground and underground facilities into one.

Integrated Land Utilization of 5 stations

The garden-type rail yard of Line 10, first of its kind in China, has been set up at Bagou, bringing more green and oxygen for urban areas. The parking lot at Songjiazhuang Station has been devised as a common depot for three subway lines. Based on the land use conditions at three subway bases, the serviceable functions of the bases have been divided reasonably to both satisfy the functional requirements of staged operation and maintenance for the whole line and relatively concentrate the maintenance facilities to fully improve labor productivity and equipment efficiency. In this way, land resources have been saved up while sharing of manpower and equipment has been realized, resulting in saving of investment of the subway on the whole.

A Panorama of Bagou Rail Yard

Many “Firsts” Scored at Home for the Project

Construction of Line 10 was technically difficult and environmental protection was also a hard job to do. As a result, UCD was bold in making innovations on structural design:Utilization of PBA was popularized at home for the first time; pile-bottom grouting technology was adopted at home for the first time in pilot tunnel; cover-excavation consequent operation was adopted at home for the first time; the application of soil nailed wall in deep foundation pit support(the depth of the foundation pit is around 15m)was adopted at home for the first time; technologies for design and construction of small-spacing and long-distance parallel shield tunnels were adopted and successfully implemented at home for the first time; protective measures such as multidimentional prestressed roof support, pile foundation underpinning, and reinforcement measures such as grouting, isolation and water-blocking technology, were adopted, which can be rated as an epitome of subway construction methods and measures in Beijing. Environmental risk source projects amounted to around 1220 along the whole loop line, one of the most difficult loop lines in risk control in the history of the Beijing subway.

Assessment of risk sources and the earmarked design system were systematically put forward for the first time in China’s domestic subway construction, being the first to use scientific processes to handle subway engineering risk sources aross the country.

People-Centered Design to Meet the Needs of Urbanization in Beijing

The operating model suited to the evacuation of emergent passenger flows from such major sport events as Olympic Games was adopted for the first phase of Subway Line 10, an auxiliary project to the Beijing Olympic Games, realizing the openning of the subway line in every 3 minutes for the first time and evacuting spectators within 70 minutes after the closing ceremony of the Olympic Games, which was highly appreciated by the International Olympic Committee. As an important measure for relieving traffic congestion in Beijing, the second phase of the project gave rise to the violent increase of passengers after it was completed. The maximum daily number of passengers reached 2.0475 million, and the annual number of passengers totaled approximately 570 million, making up 17.3% of the total number on all lines, ranking first among all the lines.

5 connected subway stations were made into separated island platform stations, first of the kind in China, being a solution to the establishment of stations at flyover areas and ensuring the structural safety of bridges. To tackle such problems as big transfer volume and hidden operational risks arising from the mismatching of traffic density at Songjiazhuang Station where three lines intersect, the“wedge-shape”program was adopted for both ends of the widened island platform for the first time in Beijing. Subsidiary halls(serving as entrance, exit and transfer halls)were set up independently and initiatively on four quadrants at Gongzhufen Station, placing passenger flows in good order and making serviceable functions more user-friendly.